-

Nina Nie

Hi there! Welcome to my shop. Let me know if you have any questions.

Nina Nie

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Unlock the Potential of Carbon Fiber: 5 Game-Changing Benefits of Waterjet Cutting

2025-09-23 11:24:46

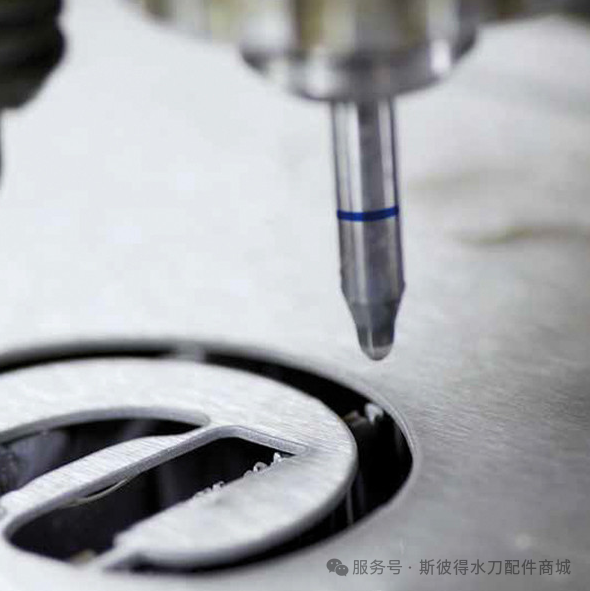

Carbon fiber composites are marvels of modern engineering: incredibly strong yet lightweight. However, their sensitivity to heat and tendency to fray make them a challenge for traditional cutting methods. Risks like delamination, burning, and micro-fractures can compromise part integrity and increase waste and cost.

There is a Smarter, Cooler Way. Discover waterjet cutting – the ultimate non-thermal, non-contact solution for flawless carbon fiber processing.

Why Waterjet Cutting is the #1 Choice for Precision Carbon Fiber Work:

Revolutionary Cold Cutting: Guarantee Zero Heat Damage

Say goodbye to thermal stress! Our waterjet process uses cold water to make perfect cuts, preserving the material's inherent strength and eliminating the risks of delamination, melting, or burnt edges. Your parts retain their full structural integrity.Kiss Mechanical Stress Goodbye: Perfect for Delicate Structures

With no brutal mechanical force, our abrasive waterjet technology gently erodes the material. This dramatically reduces edge chipping and is ideal for thin-walled and intricate components, giving you clean, undamaged parts every time.Unbeatable Precision & Repeatability for Demanding Applications

Driven by advanced CNC and CAD/CAM integration, we achieve exceptional accuracies within ±0.05mm. Whether it's a single prototype or a full production run, expect perfect consistency that meets the strictest quality standards of aerospace and automotive industries.Unmatched Versatility: Cut Any Shape, Any Complexity

From intricate contours to sharp angles, unleash your design freedom. Waterjet cutting handles any 2D shape with ease, eliminating the need for expensive tool changes and accelerating your time-to-market.A Cleaner, Greener, and More Cost-Effective Process

Experience a cleaner workshop with no harmful dust or toxic fumes. By virtually eliminating part rejection due to cutting errors, you significantly reduce material waste and lower your total cost of ownership.

Ready to Elevate Your Carbon Fiber Manufacturing?

Don't let outdated cutting methods limit your potential. Embrace the precision, safety, and efficiency of waterjet technology.

Contact us today for a free consultation or a material test cut! Let us show you how we can add value to your production process.

Tags: Waterjet Cutting, Carbon Fiber Cutting, Composite Manufacturing