Home > Blog > Waterjet Pressure Fluctuating? Don't Shut Down Yet! These Key Parts May Need Replacement!

-

Nina Nie

Hi there! Welcome to my shop. Let me know if you have any questions.

Nina Nie

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Waterjet Pressure Fluctuating? Don't Shut Down Yet! These Key Parts May Need Replacement!

2025-09-27 09:12:26

Is your waterjet pressure gauge jumping, cutting power weak, or pressure dropping unexpectedly? This doesn't just ruin your cut quality—it's a critical "health warning" from your machine!

Persistent pressure fluctuations often indicate that key wear parts have reached the end of their service life, not a major pump failure. Replacing these parts promptly is key to ensuring production stability and avoiding costly overhauls.

As Huizhou Speed Water Jet Technology Co., Ltd — an Authorized Distributor for Ceratizit and Hypertherm in China, we identify the top 3 culprits behind unstable pressure and their solutions:

Culprit #1: Worn or Damaged High-Pressure Seals

Symptoms: Pressure drops gradually, visible water leakage around the pump head, increased frequency of pump cycling.

Cause: Seals wear out over time under extreme pressure, leading to internal pressure loss.

Solution: Replace with genuine Hypertherm seal kits. OEM seals offer superior material, precision, and pressure resistance to ensure perfect sealing and restore stable pressure.

Culprit #2: Failing Check Valve

Symptoms: Needle on pressure gauge vibrates sharply, irregular patterns appear on the cut surface.

Cause: Worn valve seat or seal prevents instant closure, causing water hammer and system vibration.

Solution: Install a genuine Hypertherm check valve assembly or repair kit. OEM parts guarantee perfect fit and instant response, eliminating pressure spikes.

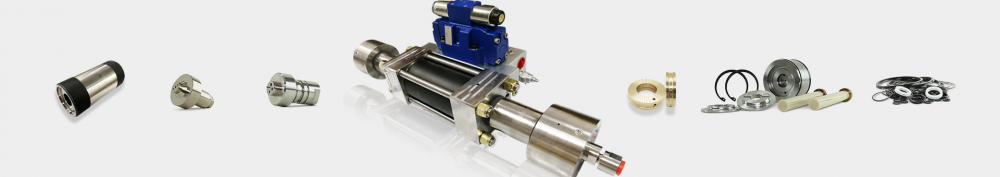

Culprit #3: Worn or Fatigued Intensifier Components

Culprit #3: Worn or Fatigued Intensifier Components

Symptoms: Failure to reach target pressure, or pressure decays during continuous operation.

Cause: Key components like the plunger inside the intensifier wear out, reducing efficiency.

Solution: Inspect and replace with genuine Hypertherm intensifier repair kits. OEM components ensure optimal performance and restore the pump's rated output pressure.

Prevention is Better than Cure: Establish a Regular Maintenance Schedule

Regularly inspect key wear parts and replace them preemptively before they fail.

Using genuine Hypertherm parts and Cerasus nozzles ensures harmony across the entire system for maximum stability and longevity.

Huizhou Speed Water Jet Technology Co., Ltd. specializes in serving the industry of ultra-high pressure water jet technology in China. Since 2010, Speed has taken advanced industrial materials as its core competitiveness and has rapidly developed into a high-tech enterprise integrating R&D, production and sales, has had great achievements in the Ultra-high pressure water jet industry, petroleum exploration equipment parts and cutting tools. With its good reputation and the trust of many well-known domestic and foreign companies, Speed has established a long-term strategic corporation with HyPrecision, Ceratizit, DTI, Sandvick etc, along with its brands of Speed Jet and Spmic, thus forming the most unique and comprehensive product system, gained the strong solution capabilities for water jet industry.

Don't let pressure problems slow you down!

Contact us now for professional troubleshooting and genuine part support!

We supply a full range of authentic Hypertherm pump repair parts to get you back to cutting quickly and reliably.

Tags: Hypertherm Pump Repair, Waterjet Seals, Check Valve